In heat-not-burn technology, it can be divided into contact type and non-contact type according to whether the heating element is in direct contact with the substrate to be heated. The contact type includes central heating and circumferential heating, and the non-contact type includes air heating and infrared heating.

The core difference between contact and non-contact heating technology lies in the heat transfer method, which directly affects the heating efficiency, user experience and technology development direction.

1. Contact heating technology

Contact heating is through the heating element (such as metal sheet, needle-shaped heating element) direct contact with tobacco for heat conduction.

- Advantages: High heating efficiency.

- Disadvantages: Prone to uneven heating; direct contact between heating sheets and tobacco substrates can easily produce tar and other contaminants.

According to the shape of the heating element, it is divided into central heating and circumferential heating.

1. Central Heating

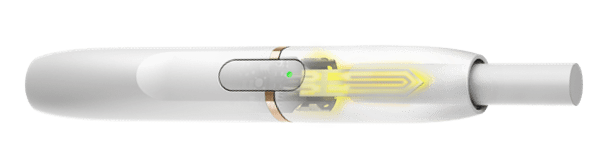

Central heating means that the heating element (such as ceramic needle, metal sheet) is directly embedded in the pod or close to the tobacco material, the heat is transferred from the inside to the outside, the heat source is in direct contact with the tobacco, and the heat utilization rate can reach 90%.

Typical example: IQOS

Its heating elements have gone through two development stages:

Resistance ceramic sheets: Used from the first generation to the fifth – generation devices. Although they heat up quickly, ceramic heating sheets are prone to breakage and difficult to clean.

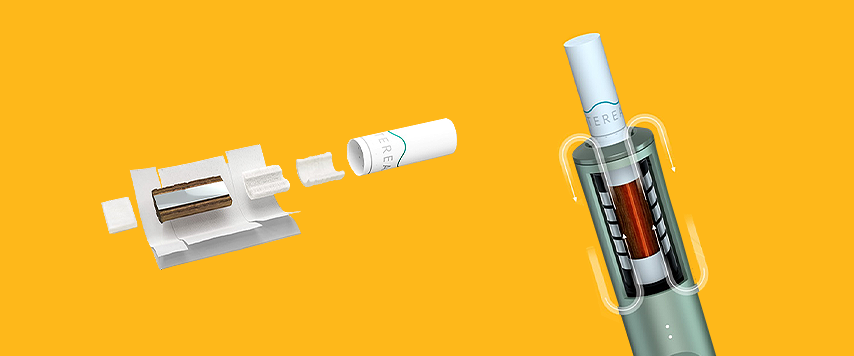

● Electromagnetic induction metal sheets: Used with the IQOS ILUMA (also known as the sixth – generation device), which perfectly solves some drawbacks of ceramic heating sheets, such as no need for regular cleaning. PMI has thus further consolidated its leading market position.

Resistance ceramic sheet, IQOS

Korean tobacco lil

Electromagnetic Induction Metal Sheet, IQOS

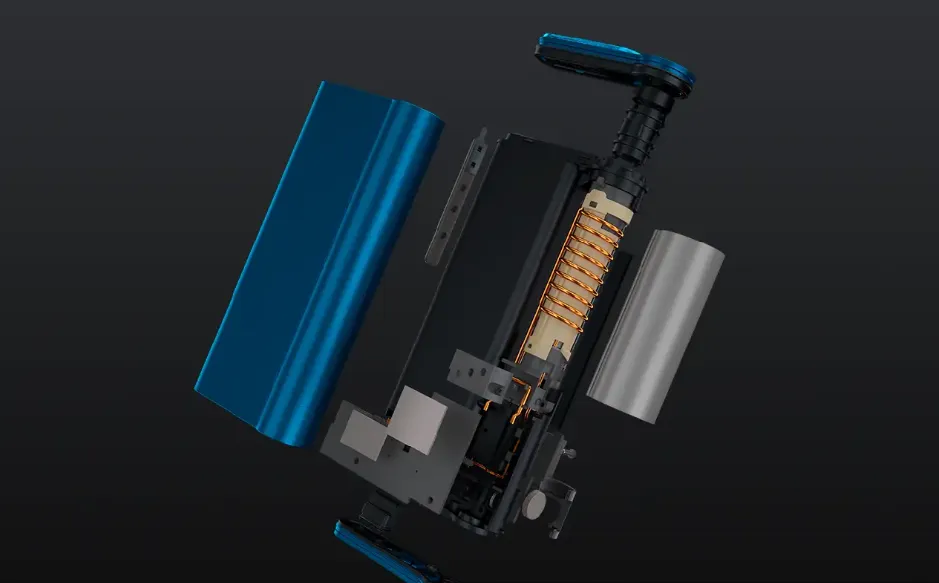

2. Circumferential heating (resistance)

The basic principle of contact circumferential heating is resistance heating, the heating element is made into a cup, wrapping the outside of the pod, and transferring heat from the outside to the inside, and the thermal efficiency is slightly lower than that of central heating (about 80-85%), which is represented by British American Tobacco Glo and Japanese Tobacco Ploom series.

British American Tobacco Glo

Nippon Tobacco Ploom

2. Non-contact heating technology

Non-contact heating means that the heating element is not in direct contact with the tobacco substrate, but generates hot air and heat radiation to heat the tobacco substrate. The advantage of non-contact heating is that it heats more evenly and does not need to be cleaned, and the disadvantage is that it is slightly inferior to contact heating in terms of heating efficiency.

1. Air heating

Air heating, also known as hot air heating, is to quickly heat the air through the bottom ceramic heating parts, and the high-temperature air flows through the pod for heating, which can simulate the traditional combustion process, gradually heat the tobacco stick, and avoid overheating the core. On behalf of HEEZY and other brands, it is the non-contact heating technology with the highest degree of marketization in the industry.

HEEZY

2. Infrared heating

Infrared heating, also known as infrared radiation heating, uses infrared radiation to resonate the molecules and atoms inside the heated object, thereby generating heat energy. Infrared heating has the advantages of strong penetration, uniform heating, high thermal efficiency, and no pollution, but the heating efficiency may be slightly inferior to the resistance and electromagnetic heating of the heat conduction mode. The case includes Anhui China Tobacco IHEA.

Infrared heating appliances, Anhui Zhongyan IHEA

3. Light heating

The core breakthrough of Alkaid’s technology lies in its light heating method, which uses a full-band light wave similar to sunlight to achieve fast and uniform heating, in addition to rapid preheating, Alkaid has also achieved significant improvements in taste and health.

It can be seen that compared with the contact technology route led by international giants, domestic enterprises focus on non-contact fields such as air heating, infrared radiation, and light heating, and break the patent blockade through differentiated innovation. In the wave of iteration of heat-not-burn technology, Chinese enterprises are expected to use non-contact heating as a breakthrough to set off a technological revolution of “corner overtaking”.